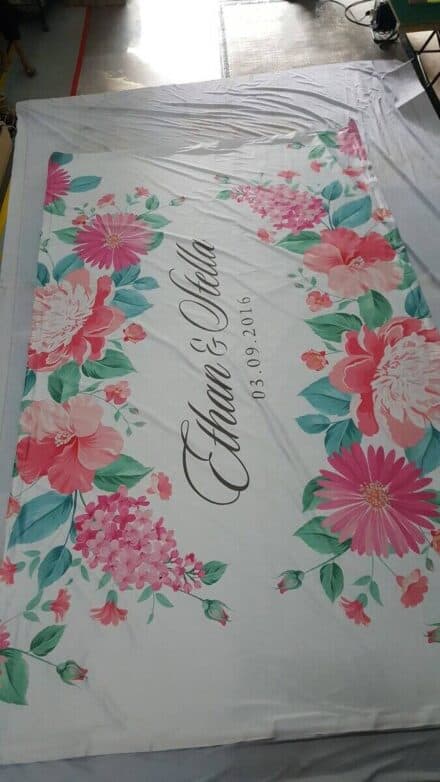

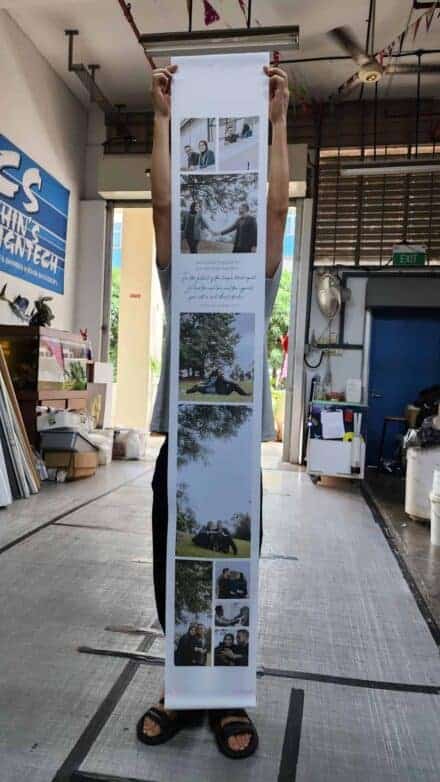

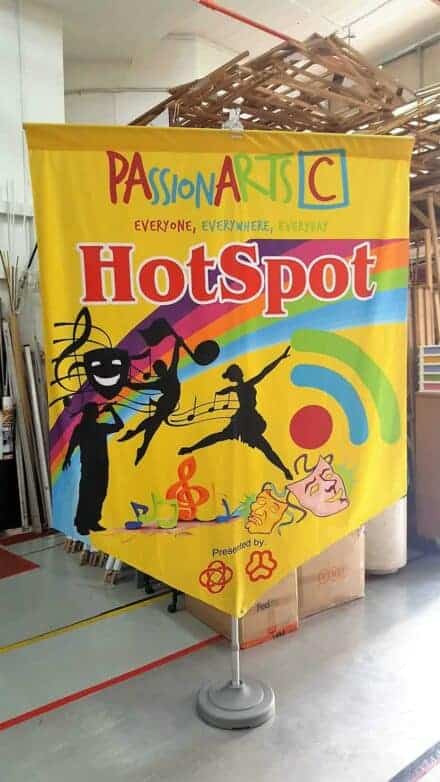

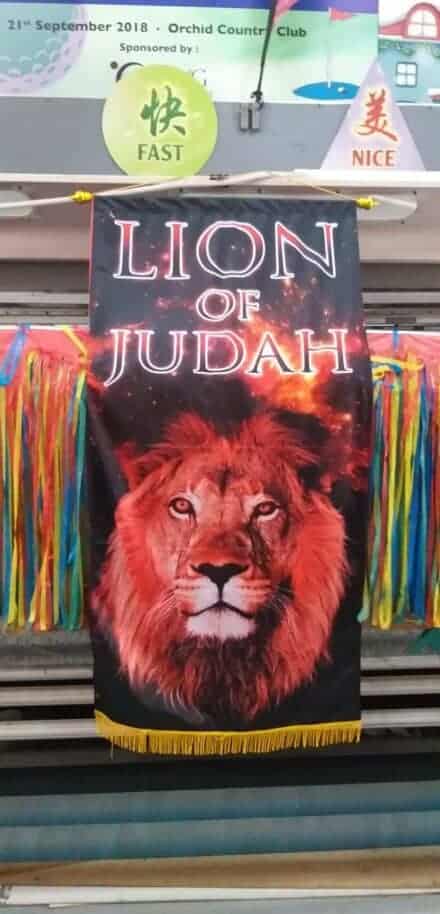

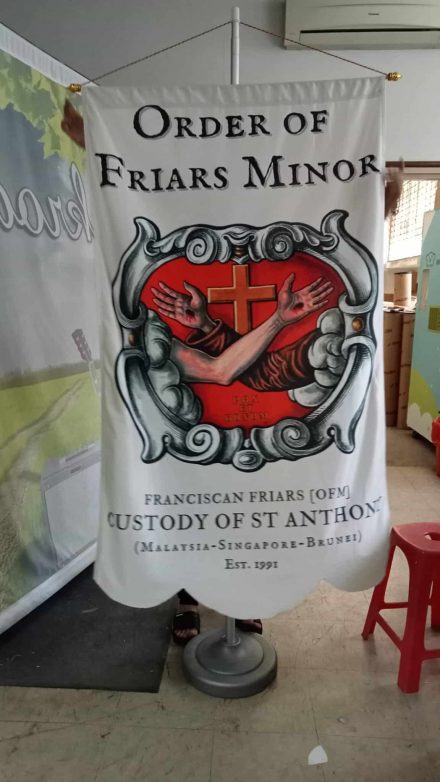

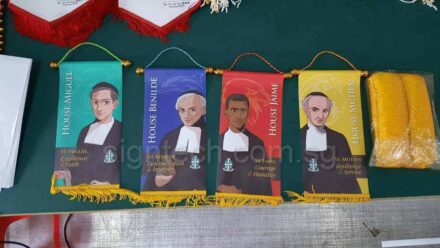

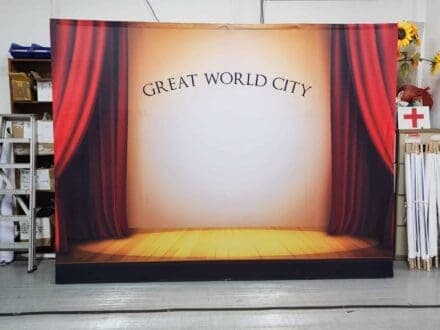

We are specialize in Custom Fabric Printing on various fabric products:

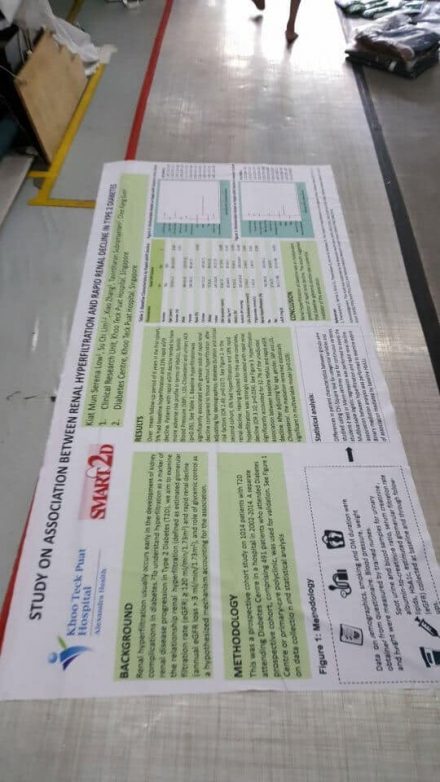

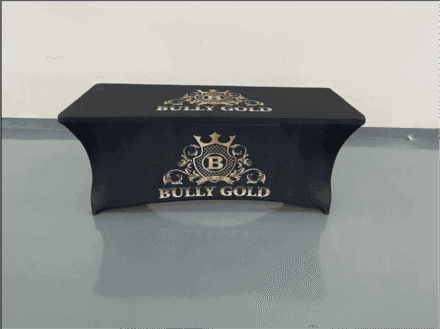

Table cloth, Cloth banner, Fabric Backdrop, Podium banner, Teardrop Banner, Feather Flag, Gazebo Tent, Custom Flag or Fabric Poster.

We use dye sublimation printing method up to 3 meter width seamless printing, digital print with dye sublimation ink directly onto fabric.

Traditional silk screen printing is slow and cannot get complicated images onto fabric.

We have large range of products on fabric printing. Promote your business perfectly with our extensive range of textile Printing.